Coming Soon

High-Voltage Charging Solutions for Tier-1 OEMs

Designed to meet OEM’s challenges to electrify heavy-duty off-highway machines

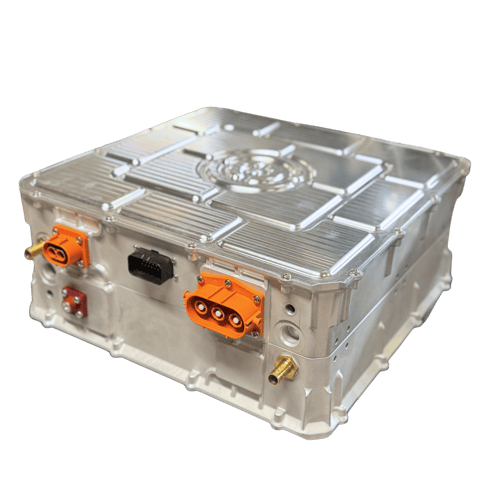

Delta-Q Technologies’ high-voltage charging solutions continue its legacy of industry-leading integration across charging, DC-DC conversion, and EVSE functionality. Now equipped with a PLC Module for DC fast charging, the 4-in-1 platform introduces a new level of streamlined, scalable charging capabilities. Delta-Q has the on-board charging capabilities to be the ideal electrification partner for the new generation of higher powered off-highway applications.

.png?width=1173&height=1500&name=Delta-Q%20High%20Voltage%20Charging%20Page%2020250130%20(1).png)

The Problems OEMs Face

High-Voltage Power Requirement

Heavy-duty applications require high power and torque. Low-voltage systems draw high current, increasing cost and complexity, so OEMs are switching to higher voltage architectures.

High-Voltage Power Requirement

Heavy-duty applications require high power and torque. Low-voltage systems draw high current, increasing cost and complexity, so OEMs are switching to higher voltage architectures.

On-Board Charging Constraints

On-board charging compensates for inconsistent access to DC Fast Charging infrastructure, but creates space, weight, durability, thermal, and safety constraints.

On-Board Charging Constraints

On-board charging compensates for inconsistent access to DC Fast Charging infrastructure, but creates space, weight, durability, thermal, and safety constraints.

Durability Requirements

Harsh environments (e.g., dust, liquid, heat, vibration) demand higher levels of ingress protection and thermal regulation. Fan-cooled units have technical & cost limitations, creating potential failure points.

Durability Requirements

Harsh environments (e.g., dust, liquid, heat, vibration) demand higher levels of ingress protection and thermal regulation. Fan-cooled units have technical & cost limitations, creating potential failure points.

System Complexity

Sourcing systems and components from different suppliers raises costs, integration complexity, and validation difficulty—and lowers accountability.

System Complexity

Sourcing systems and components from different suppliers raises costs, integration complexity, and validation difficulty—and lowers accountability.

Interoperability Mandate

Interoperability issues across charging standards and vendors lead to field failures.

Interoperability Mandate

Interoperability issues across charging standards and vendors lead to field failures.

Global Compliance

International and regional standards (e.g., NA/EU/China, ISO, IEC, J-standards) require constant engineering adaptation to maintain compliance.

Global Compliance

International and regional standards (e.g., NA/EU/China, ISO, IEC, J-standards) require constant engineering adaptation to maintain compliance.

The Solution: Integrated, High-Voltage Chargers

Reduce system complexity and cost

One enclosure with multiple charging functions minimizes boxes, interfaces, wiring harnesses, and integration time.

Reduce system complexity and cost

One enclosure with multiple charging functions minimizes boxes, interfaces, wiring harnesses, and integration time.

Market & portfolio expansion

OEMs have the flexibility to grow into new segments, optimize space, and accelerate their roadmap with Delta-Q’s comprehensive range of compact, on-board high-voltage charging portfolio.

Market & portfolio expansion

OEMs have the flexibility to grow into new segments, optimize space, and accelerate their roadmap with Delta-Q’s comprehensive range of compact, on-board high-voltage charging portfolio.

Boost reliability in harsh environments

Liquid-cooled high-voltage chargers improve thermal regulation, enabling a single coolant loop that simplifies the overall thermal architecture.

Boost reliability in harsh environments

Liquid-cooled high-voltage chargers improve thermal regulation, enabling a single coolant loop that simplifies the overall thermal architecture.

Faster validation & time-to-market

Tested with multiple EVSE and inlet vendors, and aligned with NA and EU technical and compliance standards, Delta Q’s high voltage charging solutions reduce the risk of late program redesign.

Faster validation & time-to-market

Tested with multiple EVSE and inlet vendors, and aligned with NA and EU technical and compliance standards, Delta Q’s high voltage charging solutions reduce the risk of late program redesign.

Deliver future-ready architecture

All charging solutions are designed and engineered to support evolving charging protocols and global requirements.

Deliver future-ready architecture

All charging solutions are designed and engineered to support evolving charging protocols and global requirements.

High-Voltage Charging Solution Capabilities

Building on Delta‑Q’s foundation of quality and reliability, the high-voltage charging platform expands and advances the company’s charging technology, meeting the electrification needs of material handling, e‑mobility, and other off‑highway markets.

This integrated on-board architecture brings together:

- On-board charging for high-voltage systems

- High-power DC-DC converter to power auxiliary systems without a separate unit

- Built-in EVSE Interface (EVC) for level 2 AC charging support

- PLC Module for level 3 DC fast-charging support

- Liquid cooling for harsh environments

Industries & Applications

Construction

Agriculture

.png?width=127&height=127&name=Agriculture%20(1).png)

Material Handling

Mining

FAQ

A high‑voltage on‑board charger converts AC power from a wall outlet or EV charging station into DC power to charge a high‑voltage battery pack, typically between 100 and 800 V. Manufacturers commonly use high‑voltage architectures in automotive, heavy industrial or off‑road equipment, including construction, mining, and agriculture.

On‑board chargers give operators flexibility by allowing the machine to charge wherever and whenever an available power source is present.

AC charging and DC charging refer to two different methods for charging EV batteries:

- AC is slower, but safer, for battery longevity and usually used for overnight charging.

- DC is much faster, but produces heat and can diminish battery capacity if done too frequently.

An EVSE (Electric Vehicle Supply Equipment) interface refers to the standardized connector design(s) used to plug an EV into a charger. These connector types, like SAE J1772, Type 2, or CCS, vary by region and determine what cables and charging stations a vehicle can use.

Powerline communication (PLC) refers to an electrical line that delivers both power and data. It’s necessary to support DC fast charging, where the vehicle and charging station must communicate constantly about charging speed, safety, temperature, and authentication.

Heavy-duty EVs require liquid-cooled chargers due to their substantial thermal management requirements. However, heavy-duty EVs also benefit significantly from liquid cooling, as they are likely equipped with a coolant architecture to regulate the thermal load on other systems. On-board chargers can be integrated with these systems (e.g., battery, motor, and inverter) to provide thermal regulation without adding too much space or weight.

Integration reduces system costs in several ways. First, integrations that bundle all system components into a single box reduce the cost of additional parts, such as wiring harnesses. Second, OEMs can shift from managing orders and fulfillment across numerous suppliers to buying from a single supplier, thereby eliminating administrative redundancy (e.g., processing, validation). Third, if any adjustments or issues arise, one supplier can take accountability and resolve the problem more easily, minimizing impacts such as stalled production or recalls.

OEMs traditionally source multiple components from different vendors to create the charging system, such as the on‑board charger, DC‑DC converter, EVSE interface, and PLC module. This often creates a system with multiple boxes, harnesses, connectors, and integration points, which introduces cost, complexity, and potential failure modes.

Because these components must communicate and operate together reliably, integration becomes a major engineering challenge. Working with several suppliers can slow development, introduce risk, and increase costs.

A 4‑in‑1 system solves this by combining all four functions into a single enclosure. This approach:

- Reduces component count and wiring

- Simplifies integration and validation

- Minimizes failure points

- Lowers overall system cost

- Speeds up development and reduces risk

Instead of coordinating with multiple suppliers, OEMs can rely on a single partner that delivers a fully integrated charging solution, supporting customization as needed.

The high‑voltage charging platform has been validated with multiple EVSE manufacturers as well as various EVSE inlet suppliers. It is also designed to comply with several North American and European charging standards, including ISO 15118, IEC 61851, J1772/J3068 and other standards.

Delta-Q is in the process of finalizing the high voltage series. Development samples for system fit and interoperability testing will be available in 2026. To be the first to learn about detailed specifications and confirmed launch dates, join the waitlist.

Why Delta-Q Technologies?

With over 26 years of industrial and commercial charging experience, Delta-Q Technologies continually demonstrates a commitment to the highest engineering and partnership standards. The engineering depth and expertise Delta-Q Technologies provides today (e.g., HV, PLC, cooling) directly builds upon its first charge algorithms and lab testing. All charger models undergo extensive evaluation within Delta-Q Technologies’ interoperability testing lab and under extreme conditions to ensure they meet OEMs’ and operators’ needs.

As part of the ZAPI GROUP ecosystem—a global electrification leader across motive, autonomy, telematics, and other applications—Delta-Q Technologies is optimally positioned to deliver turnkey integrations and application-specific charging solutions.