The NEWLY Expanded RQ Battery Charger Series:

Optimized for volume production,

timelessly reliable to sustain strong OEM legacies.

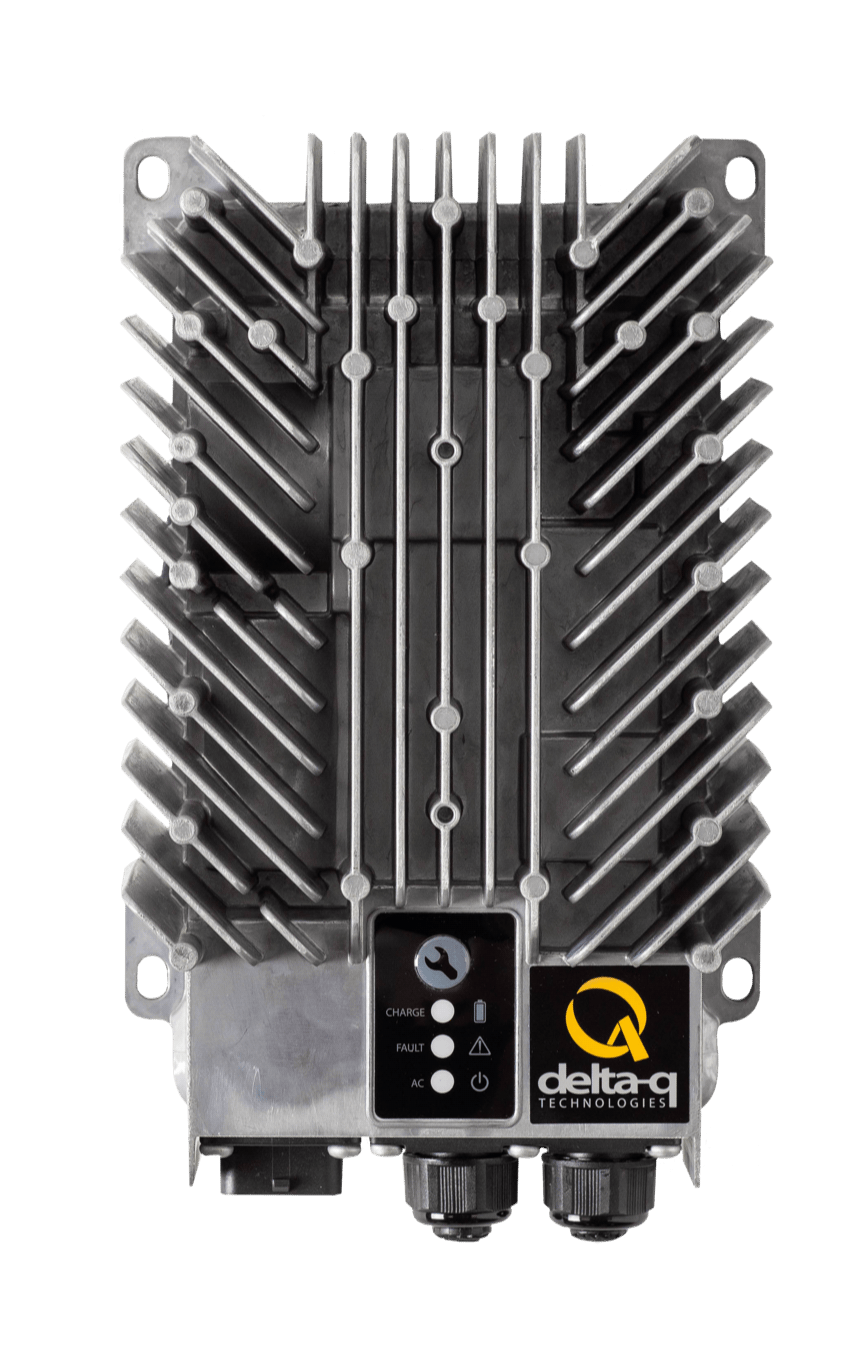

Major OEMs can rely on the RQ Series 350 W and 700 W battery chargers. Built for high-volume production, the user-friendly design is easy to install and integrate with leading-edge systems and rugged enough to uphold the largest brand names in outdoor power equipment, golf/utility vehicles, e-mobility/low-speed EVs, material handling, and mobile elevated work platforms.

*Product shown is the RQ700

Suitable for:

12 V, 24 V, 36 V, 48 V Charging Voltages & 12 V Auxiliary Output

The RQ350 and RQ700 are 350 W and 700 W chargers that are engineered to be compatible with common battery chemistries and nominal voltages between 12 V and 48 V. The RQ700 also features a 12 VDC, 400 milliamp (mA) auxiliary power supply to operate system components.

Sealed & Rugged Design

The sealed, ruggedized, IP66 and 67-rated design protects against shock, vibration, and moisture ingress, making the RQ Series charger ideal for operation in harsh environments.

Exceptional Performance

The RQ Series charger's robust construction and advanced software (with over 200 battery manufacturer validated charging profiles) delivers the right charging profile for optimal system performance and battery life.

Enhanced CANbus Communication and UDS Support

CAN open and SAE J1939 protocols allow for communication with vehicle, telematics and BMS system. Unified Diagnostic Services (UDS) offers the ability to use standardized service and upgrade diagnostic tools.

-1.png?width=250&height=250&name=Untitled%20design%20(8)-1.png)

The Interactive User Display

View charging status, completion, errors and faults on the three LED display, and easily change active charge algorithms with the push-button.

-1.png?width=500&height=500&name=Untitled%20design%20(12)-1.png)

Installation Cables

The RQ700 has a user-friendly design, complete with installation cables that are tested and validated by the company’s engineering team to ensure they meet industry and customer requirements for cables and connectors. This bundle eliminates the extra time, expense and effort for customers to procure their own cables, adding convenience for high-volume applications.

"The fact that Delta-Q is making high quality chargers…allows us to trust that when we sell one to our customer, we’re not going to get the charger back. Which is why [Delta-Q chargers are] our primary on-board charger that we recommend to our customers.”

—Dan Dressel, Director, OEM and National Accounts at Fullriver Battery USA

About Delta-Q Technologies and ZAPI GROUP

Delta-Q Technologies is charging the future and driving the world’s transition into electric energy! We collaboratively design, test, and manufacture robust battery chargers that improve the performance of our customer’s electric drive vehicles and industrial machines.

As the supplier of choice for Tier 1 OEMs, we use our values, perseverance, and engineering expertise to guide our customers through the electrification process for a sustainable world.

We're also part of the ZAPI GROUP, a global leader in electronic speed controllers and associated products for battery and hybrid-powered electric vehicles.

Headquartered in Vancouver, Canada, Delta-Q’s team and distribution spans five continents to service industries such as electric golf cars, lift trucks, aerial work platforms, e-mobility, floor care machines, utility/recreational vehicles and new markets, like outdoor power equipment.